Fokker DVII German Fighter Biplane

The Fokker DVII or DV7 was one of the outstanding German Luftwaffe fighters of World War One. With it German hoped to regain Aerial dominance over Allied fighters on the WW1 Western Front. It was built by a Dutchman not a German. Anthony Fokker was building aircraft in Germany from his factory located at the Johannisthal airfield, near Berlin. In 1913 the factory moved to Schwerin. Reinhold Platz was one of Fokker's designers and he came up with some novel ideas which he built into prototype planes. These included a car type radiator in front of the engine and cantilever wings with no external bracing wires.

At the end of January, 1918, the first competition for D class machines was held at Adlershof. German pilots from the front flew new prototype aircraft to choose which one would go into production. Reinhold Platz's entry called V.11 (V=Versuchsmachine Experimental aircraft No. 11) came out as the ultimate winner, and was designated D.VII. It was a far superior design to the earlier Fokker Triplane used by Baron Manfred von Richthofen's flying Circus. Richthofen promoted the development of the Fokker D.VII biplane fighter. He had submitted suggestions as to what was needed to overcome the deficiencies of the then current batch of German fighter aircraft. He never had an opportunity to fly the Fokker DVII in combat as he was killed just days before it entered service.

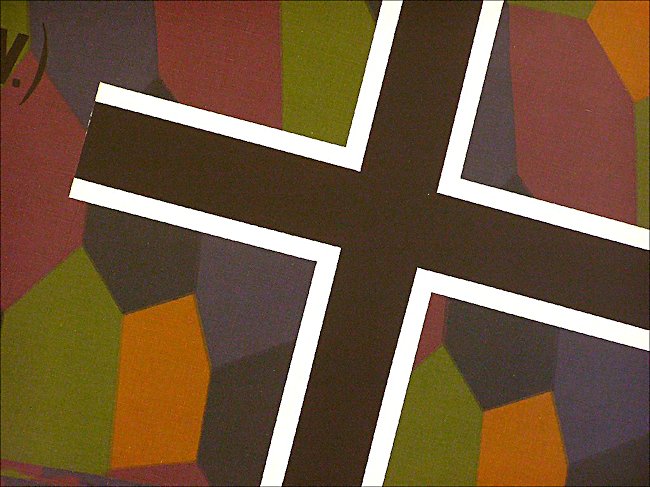

Photograph taken at the RAF Museum, Hendon, London NW9 5LL England

Anthony Fokker's company were given large contracts for the D.VII by the German government, but Fokker's factory at Schwerin did not have the capacity to build large numbers of the D.VII biplane fighters. Fokker's rival Albatros had to manufacture the D.VII under license at their factories at Johannisthal and the Ostdeutsche Albatros Werke at Schneidemuhl. Fokker received a 5% fee from Albatros for every D.VII they built. The exact numbers of Fokker DVII constructed is not known but it is estimated to be in the region of 2,000.

Unlike the British RFC Sopwith Camel the Fokker DVII had superb handling characteristics and was fairly easy to fly. The Allied fighters were mainly made of wood. The German Airforce Fokker DV11 had a welded steel tube fuselage frame. The Germans used American car making mass production techniques to turn out as many of these first class fighters as they could. The Fokker D.VII is widely regarded as the best German airplane of the war and was dubbed the "Flying Razor" by Allied pilots, it had the distinction of scoring the last aerial victory of the war.

Photograph taken at the RAF Museum, Hendon, London NW9 5LL England

There was a time when every machine that made a raid on London, or in use at the front for that matter, was labeled as a Fokker because of their feared reputation. Its speed, agility and firepower so terrified the Allies that it was the only weapon mentioned by name in the armistice on 111th November 1918. The Germans were ordered to surrender "1,700 fighting and bombing aeroplanes-in the first place, all D7's and all night bombing aeroplanes". This instruction was ignored. Some were flown back to Germany by their pilots and hidden in barns, garages, warehouses and sheds.

Some of the Fokker DV11 flown to the designated collection airfields of the Inter-Allied Control Commission, were wrecked by their German pilots on landing or during taxiing to frustrate the allied victors. After the war, some were sold abroad the Americans, French and British kept some for themselves. Crafty Dutchman, Anthony Fokker smuggled six trains with sixty wagons each full of aeroplanes and tools to Holland. Among these were 120 Fokker D.VII's. The air forces of Switzerland, Holland and Lithuania were still using Fokker DV11 at the beginning of world war two.

Photograph taken at the RAF Museum, Hendon, London NW9 5LL England

You can see original WW1 Fokker D.VII fighter's in the Royal Air Force Museum, Hendon in England, at the Militaire Luchtvaart Museum, Soesterberg in Holland, there are two in Canada, one at the Brome County Historical Society, Knowlton, Quebec and another at the National Aviation Museum, Ottawa. Germany has one at the Deutsches Museum, in Munchen. France has one in the Musee de l'air et de l'espace, Le Bourget and you can see one in the National Air And Space Museum in Washington DC, USA.

The following is an extract from July 25 1918 issue of Flight magazine. It is a report on a captured crash landed Fokker DV11; Except for the fact that it is a biplane, the new Fokker product is very similar to the Fokker triplane. The body construction is the same, and the wireless wing design is very similar to that of the Fokker triplane. There is one notable departure, however; the engine fitted has evidently been a stationary water-cooled one, probably a 180 Mercedes.

Photograph taken at the RAF Museum, Hendon, London NW9 5LL England

The body of the Fokker biplane is built throughout of steel tubing, the method of joining the struts and cross members to the corner rails being the same as in the Fokker triplane, and the tubular quadrants serving as an anchorage for the cross-bracing wires being also exactly of the same type as in the previous machine. The wire bracing, as before, is simply doubled over the terminals, and only a single strainer being employed in each double wire. The tail plane and elevator are similar in shape and construction to those of the triplane. The rudder is balanced, as in the triplane, but is preceded by a, triangular vertical fin, which has probably been necessitated by the larger water-cooled engine, which gives a deeper body in front. The vertical fin is chiefly remarkable on account of the fact that it has its front attachment slightly off-set to the left, probably to counteract the tendency, caused by the torque, to turn to the left.

The pilot's seat is similar to that of the Fokker triplane, and is provided with the same wing nuts for quickly adjusting its height to suit individual pilots. In the machine exhibited, the control lever is missing, but from the parts remaining in place it would appear that there has been a forked lever pivoted on a longitudinal rocking shaft, which in turn carried the cranks for the aileron control cables, which pass over pulleys in the top plane in the manner illustrated in our description of the Fokker triplane.

The engine, which, as we have already pointed out, has been of the water-cooled type, is mounted on a structure built entirely of steel tubes. The two engine bearers are large diameter tubes, supported from the corner rails by small diameter tubes apparently of very light gauge. The tanks are placed immediately behind the engine, the right-hand compartment of the large main tank carrying the oil, and the left-hand compartment the petrol. A Vee-type radiator of honeycomb formation is built into the nose of the body, and is provided on the inside with a shutter for adjusting the cooling

The under carriage is of very similar design to that of the Fokker triplane, the axle being enclosed in a wing section of three-ply wood. The shock absorbers are of the spiral spring type, and are covered, in by a woven casing. A feature of the Fokker construction, both as exemplified in the Fokker triplane and in the present machine, is the large amount of welding employed, and the manner of employing it. After an examination of the biplane, one is apt to come to the conclusion that the designer of the Fokker biplane places implicit faith in has welders, and, we are bound to admit with very good cause. The welding is excellently done throughout the machine, but the way the designer has seen fit to employ the welded joints is not above criticism. Thus, on examining the undercarriage, one finds that the lug, a simple forked arrangement, to which the cross bracing cables of the front bay are attached, is simply welded to the wall of the chassis strut without any internal reinforcement. The result, as regards one of the lugs, has been that in the shock of landing the lug has pulled out bodily a large triangle of the strut wall. The welded joint itself has remained intact, but it appears probable that the welding process has weakened the metal of the strut wall so that under the sudden stress of a rough landing this part gave way first, leaving the joint itself intact. This speaks well for the welder, but less so for the designer.

With regard to the wings of the Fokker biplane, these have been designed on the wireless principle, as in the case of the Fokker triplane. There is this difference, however, that whereas in the Fokker triplane the two spars were placed so close together as to form a single box, they are quite separate in the biplane, owing, no doubt to the outer chord, which with its consequent greater travel of the centre of pressure, made it necessary to place the spars farther apart than could conveniently be done with the single-box arrangement. Each of the spars is built up of spruce flanges, connected on front and rear faces by three-ply webs, the whole forming a box. Both spars taper in a vertical as well as in a horizontal plane. The spars of the upper wing are of uniform width and depth over the portion between the body struts, and taper, from the point of attachment of these struts, to the wing tip, both in front elevation and in plan.

The lower wing spars are of uniform section for the width of the body, and hence taper with a straight taper to the tips. The wing section appears to be similar to, but an enlarged edition of, that employed in the Fokker triplane. It is extremely deep compared with any modern standard, about 9 1/2 ins. being the maximum thickness of the top plane. The bottom plane, which is of smaller chord, appears to be a geometrical reduction of the top one, and is of considerably smaller chord. The actual dimensions have not yet been ascertained, as the machine in question is very considerably damaged.

As far as can be ascertained at present, the chord of both wings was uniform from root to tip, which fact would appear to indicate that the section from point to point varies from one of very great depth and thickness in the centre to one of more orthodox section near the tips. The aerodynamic effect of this would be of interest, and we cannot in this connection refrain from again urging, as we have repeatedly done in the past, the advisability of having tests made on all available enemy aerofoil sections and the results published. A section like the Fokker is not generally credited with any very high efficiency, but the mere fact that it has been retained in a design, examples of which have been built not more than three months ago, would certainly appear to indicate that it has not been found in practice to be so inferior as to outweigh any other advantages that may attend its employment.

The wing ribs of the Fokker biplane are somewhat similar to those of the triplane, but a difference was noticed in the construction of the flanges In the triplane the thin three-ply web was accommodated in a narrow groove in the top and bottom flanges, but so narrow was the web that quite 50 per cent, of the tacks missed the web altogether and simply served to weaken the flanges. In the biplane it is not, therefore, surprising to find that an attempt has been made to eliminate this defect. This attempt has taken the form of the employment of a two piece flange instead of the old grooved one-piece flange. Instead of vertical tacks the two halves of the two-piece flanges are held together and to the thin web by transverse tacks driven through alternately from right and left, and riveted over.

The manner of supporting the top plane is somewhat different from the method employed in the Fokker triplane. No wire bracing whatever is used, the necessary transverse rigidity being provided by the arrangement of the body struts. Sloping outwards from the body is a system of struts, all stream line steel tubes. One strut runs from the lower corner rail of the body to the rear spar. A set of three struts unite in a welded joint secured to the top spar by a single bolt. Each of these three struts is welded to a portion of the body, so that when the top plane is removed, a pyramid of steel tubes remains in place on the body, sloping upwards and outwards from the sides. The front one of these struts is welded to the tubular engine bearer, projecting through an opening in the metal body covering. The middle strut is welded to the bottom corner rail at the point where is, attached the front strut of the undercarriage, and the third strut is also welded to the bottom -corner rail, or, more correctly speaking, to a rail running above the spars of the lower wing, at the point where it is crossed by the front spar. The upper front spar is thus rigidly secured, whereas provision has been made for an adjustment of the angle of incidence by fitting into the end of the strut running from the rear spar to the lower body rail a threaded eye bolt fitting into a socket on the lower rail.

Incidentally it might be mentioned in this connection that the upper plane is marked Anstellwinkel (angle of incidence degrees.) Whether or not the bottom plane is also set at no angle of incidence we have not yet been able to ascertain. The mounting of the bottom plane is slightly different to that of the bottom plane of the Fokker triplane. In the latter provision was made for a slight adjustment of the angle of incidence, but in the biplane no such arrangement is to be found, the spars being rigidly attached to the body corner rails.

Only one pair of inter-plane struts connect the upper and lower wings on each side. These are in the form of an N, the joints between the members being welded. The joints between the legs of the N and the wing spars are in the form of ball and socket joints, those for the front top spar and rear bottom spar being fixed, while threaded bolts screwed into the end of the struts meeting the upper rear and lower front spars provide means for adjusting the incidence.

No lift or landing wires are fitted, the deep spars being relied upon to resist the bending moments without external aid. Internally the wings are drift-wired with solid circular section steel wire, of 'heavy gauge, but not in duplicate. It was noticed that one of the lugs to which a drift wire was attached had sheared through, but we should hesitate to say that this necessarily indicates that here was a weak point regarded from the point of view of flying stresses, as the wing had evidently been badly damaged by the machine turning over on landing.

The armament of the Fokker biplane consists of two Spandau guns mounted on top of the body and synchronised in the usual manner to fire through the propeller. As regards the covering of the Fokker biplane this is chiefly remarkable, in the specimen under review, on account of the colours in which it is painted. The front portion of the body and the top surface of the top plane are painted a deep vermilion, while the rear portion of the body is painted white. The lower surfaces of the top plane and the bottom plane are camouflaged in the usual German manner by a printing in different colours of lozenge-shaped figures. The tail plane and elevator are painted black, with the exception of a parallel portion of the top surface, which is painted white like the body

WW1 German aircraft books

Tweet